The exit pit of a horizontal directional drilling operation is a particularly hazardous location.

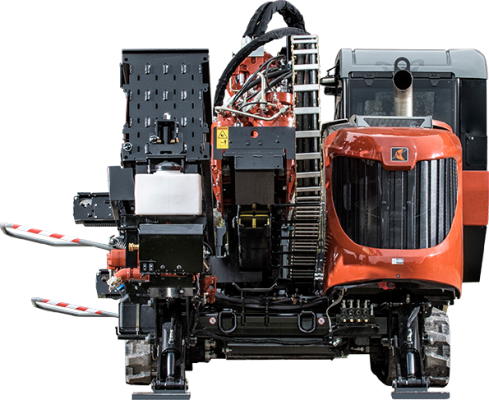

AT40 All Terrain Directional Drill

Optimized for industry-leading performance and productivity when drilling in hard rock conditions, the Ditch Witch AT40 All Terrain is designed with an advanced version of the proven Ditch Witch All Terrain drilling system. The updated, two-pipe system boosts power to the bit—33 percent more torque than the competition. The drill leverages the next-generation features of the JT40 model so you get increased jobsite cycle times, improved durability and greater control.

The AT40 All Terrain is designed with an advanced, two-pipe drilling system for industry-leading power to the bit. The enhanced system boosts power and productivity when drilling and steering in hard rock conditions.

The inner pipe works as a mechanical motor, driving the bit during the bore, and the outer pipe thrusts the bit forward while steering the drill shaft. During backreaming, the outer pipe transmits full machine torque downhole.

All Terrain technology enables enhanced rock drilling at a low fluid level, decreasing overall jobsite waste, minimizing cleanup and reducing environmental impact.

The optimized system utilizes true 15-ft length drill pipe, allowing a total of 360 feet of drill pipe to fit onboard for reduced jobsite cycle times.

Patented All Terrain connection provides a more reliable connection for optimized performance and steering.

The RockMaster®All Terrain housing has a modular design that allows it to adapt to two different sizes of bits, allowing a 2.875 and 3.5 regular API connection.

The housing features an industry-exclusive, double-layer seal design with high-capacity bearings to increase downhole life and reliability, which minimizes maintenance and cuts any associated rebuild costs in half.

A patented, steering-offset design eliminates the need for a universal CV joint, reducing fatigue in shaft and allowing a two-degree bend for more effective and responsive steering in hard rock conditions.

Equipped with a 160-gross-hp, Tier 4 Cummins® diesel engine, the AT40 All Terrain provides 14 percent more horsepower than competitive models in its class. A Tier 3 engine option is available for less regulated countries.

With 40,000 pounds of thrust and pullback, the AT40 All Terrain provides 30 percent more thrust in a more compact unit than competitive models in its class.

The machine offers an innovative two-speed, rotational drive system, producing 5,500 ft·lb of torque for greater efficiency and uptime.

The newly updated hydraulic platform utilizes the Ditch Witch-proven technology to provide the most efficient power downhole.

Equipped with a 70-gpm, 1,100-psi mud pump, the AT40 All Terrain has increased fluid course from the mud pump to the swivel, for more downhole flow capabilities.

The machine includes a patent pending reversible pipe box for added jobsite versatility.

Patent-pending open-sided vise wrenches on the unit are rotated toward the operator enhancing visibility.

The drill features a unique add-a-pipe design, which allows operators to manually insert additional sticks of drill pipe when pipe runs out, improving overall productivity.

The machine provides industry-leading visibility with the best view to all critical vision points, including ground entrance, wrenches, shuttle-retract location, and rear connection.

The AT40 All Terrain is equipped with the choice of a fully enclosed cab, with all tinted, glass side paneling, or an open operator’s station.

The ergonomic station was designed specifically for an HDD operator, featuring a heated seat with adjustable suspension and increased legroom.

The operator’s platform is equipped with telescoping capability providing the optimal drilling view for improved jobsite operations.

Equipped with two seven-inch LED screens for better visibility into all machine functions, diagnostics, and bore tracking information.

A real-time carriage-position indicator provides operators insight to the exact carriage position for increased productivity and intuitive operation.

The machine is equipped with radial operator control (ROC)—the multifunctional controller is highlighted on the machine display when activated for improved control efficiency.

The AT40 All Terrain is equipped with swing-out, lift-off service doors for easy access for machine maintenance and serviceability.

With no grease zerks and easy access to all service points in one spot, maintenance is simplified and total cost of ownership reduced.

Integrated pipe lubricator makes it easier for operators to change out lubrication buckets for more efficient machine maintenance.

The AT40 All Terrain minimizes pipe-entry distance for increased support for the drill pipe as it enters the ground—this reduces wear on guide blocks and decreases the overall footprint on a job.

The AT40 All Terrain is equipped with a modular stake down system with two available options, standard and heavy-duty, that can now be feathered for more precise control.

The advanced remote control gives operators the ability to set up the rig outside of the cab allowing more precise positioning of the unit on the job.

The controller includes multi-mode ground drive; dual, independent stabilizers, stake down, cab traverse, and dual pivot.

As with all Ditch Witch equipment, the AT40 All Terrain is backed by a worldwide network of dealerships you can count on for unmatched commitment to your success. From genuine Ditch Witch parts to factory-trained service and expert advice, your Ditch Witch dealership is your trusted partner.

| OPERATION | U.S. | METRIC | |

|---|---|---|---|

| Spindle speed, max | 225 rpm | ||

| Spindle speed, max (AT inner spindle) | 280 rpm | ||

| Spindle torque, max | 5,500 ft·lb | 7457 N·m | |

| Spindle torque, max (AT inner spindle) | 2,000 ft·lb | 2760 N·m | |

| Carriage thrust travel speed | 180 fpm | 55 m/min | |

| Carriage pullback travel speed | 180 fpm | 55 m/min | |

| Thrust force | 40,000 lb | 178 kN | |

| Pullback force | 40,000 lb | 178 kN | |

| Backreamer diameter | Soil dependent | ||

| Ground travel speed | |||

| Forward/reverse | 3 mph | 4.8 km/h |

| POWER (TIER 4) | U.S. | METRIC | |

|---|---|---|---|

| Engine | Cummins® QSB4.5 | ||

| Fuel | Diesel | ||

| Cooling medium | Liquid | ||

| Injection | Direct | ||

| Aspiration | Turbocharged & charge air cooled | ||

| Number of cylinders | 4 | ||

| Displacement | 275 in3 | 4.5 L | |

| Bore | 4.21 in | 107 mm | |

| Stroke | 4.88 in | 124 mm | |

| Manufacturer’s gross power rating | 160 hp | 119 kW | |

| Rated speed | 2,300 rpm | ||

| Emissions compliance | EPA Tier 4 | EU Stage IV |

| POWER (TIER 3, LRC) | U.S. | METRIC | |

|---|---|---|---|

| Engine | Cummins QSB4.5 | ||

| Fuel | Diesel | ||

| Cooling medium | Liquid | ||

| Injection | Direct | ||

| Aspiration | Turbocharged & charge air cooled | ||

| Number of cylinders | 4 | ||

| Displacement | 275 in3 | 4.5 L | |

| Bore | 4.21 in | 107 mm | |

| Stroke | 4.88 in | 124 mm | |

| Manufacturer’s gross power rating | 148 hp | 110 kW | |

| Rated speed | 2,300 rpm | ||

| Emissions compliance | EPA Tier 3 | EU Stage IIIA |

| DIMENSIONS | U.S. | METRIC | |

|---|---|---|---|

| Length, mobiling | 295 in | 7.50 m | |

| Length, trailering | 290 in | 7.37 m | |

| Width, w/open station | 89 in | 2.26 m | |

| Width, w/cab | 93 in | 2.36 m | |

| Height, w/cab | 114 in | 2.90 m | |

| Operating mass, no pipe | 21,600 lb | 9800 kg | |

| Entry angle | 20-29° | ||

| Angle of approach | 17° | ||

| Angle of departure | 17° |

| WEIGHT CONFIGURATION | U.S. | METRIC | |

|---|---|---|---|

| Cab option | 690 lb | 310 kg | |

| Standard anchor option | 750 lb | 340 kg | |

| HD anchor option | 1,290 lb | 590 kg | |

| Deduct Tier 3 engine option | 165 lb | 70 kg |

| DRILLING FLUID SYSTEM | U.S. | METRIC | |

|---|---|---|---|

| Pressure, max | 1,000 psi | 69 bar | |

| Flow, max | 70 gpm | 265 l/min |

| FLUID CAPACITIES | U.S. | METRIC | |

|---|---|---|---|

| Hydraulic reservoir | 17 gal | 64 L | |

| Fuel tank | 56 gal | 212 L |

| POWER PIPE® HD | U.S. | METRIC | |

|---|---|---|---|

| Length of drill pipe, nominal | 180 in | 4.57 m | |

| Diameter of drill pipe, tool joint end | 3.13 in | 80 mm | |

| Diameter of drill pipe | 2.81 in | 71 mm | |

| Bend radius, min | 146 ft | 45 m | |

| Weight of drill pipe, lined | 150 lb | 68 kg | |

| Weight of drill pipe & large box (40 pipe) | 7,140 lb | 3240 kg | |

| Weight of drill pipe & small box (20 pipe) | 3,797 lb | 1720 kg |

| ALL TERRAIN PIPE | U.S. | METRIC | |

|---|---|---|---|

| Length of drill pipe, nominal | 180 in | 4.57 m | |

| Diameter of drill pipe, tool joint end | 3.75 in | 95 mm | |

| Diameter of drill pipe | 3.07 in | 78 mm | |

| Bend radius, min | 170 ft | 52 m | |

| Weight of drill pipe | 231 lb | 105 kg | |

| Weight of drill pipe & large box (24 pipe) | 6,350 lb | 2880 kg | |

| Weight of drill pipe & small box (12 pipe) | 3,450 lb | 1560 kg |

| HIWS1 PIPE | U.S. | METRIC | |

|---|---|---|---|

| Length of drill pipe, nominal | 180 in | 4.57 m | |

| Diameter of drill pipe, tool joint end | 3.10 in | 79 mm | |

| Diameter of drill pipe | 2.63 in | 67 mm | |

| Bend radius, min | 145 ft | 44 m | |

| Weight of drill pipe | 165 lb | 75 kg | |

| Weight of drill pipe & large box (35 pipe) | 6,915 lb | 3140 kg | |

| Weight of drill pipe & small box (15 pipe) | 3,287 lb | 1490 kg |

| BATTERY (2 used) | |||

|---|---|---|---|

| SAE reserve capacity rating | 195 min | ||

| SAE cold crank rating @ 0°F (-18°C) | 950 amps |

We’ve made a wide variety of valuable safety information available in one convenient location. Ditch Witch Safe is dedicated to providing the resources you need to operate your equipment safely.